When it comes to home heating systems, furnaces are among the most common and reliable options. At the heart of these systems lies a crucial component known as the furnace heat exchanger. This integral part plays a significant role in the efficiency and functionality of the entire heating system. In this comprehensive guide, we’ll delve into the various aspects of furnace heat exchangers, exploring their importance, functionality, maintenance, and more.

Understanding the Functionality of a Furnace Heat Exchanger

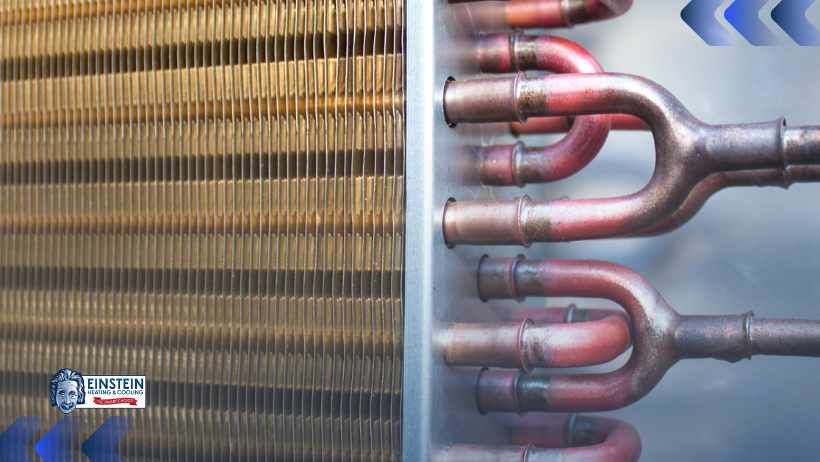

A furnace heat exchanger is a key component responsible for transferring heat generated by the combustion process to the air circulated throughout your home. It consists of a series of tubes or coils through which hot gases pass, heating the metal surfaces in the process. As the air from your home passes over these heated surfaces, it absorbs the heat, which is then distributed through the ductwork via a blower motor.

Importance of Efficient Heat Transfer

- Efficient heat transfer is essential for ensuring that your furnace operates at optimal efficiency, providing consistent and comfortable indoor temperatures while minimizing energy consumption.

- A well-functioning heat exchanger maximizes the heat output of your furnace, ensuring that your home stays warm during the colder months without putting excessive strain on the system.

Impact on Energy Efficiency

- The efficiency of a heat exchanger directly impacts the overall energy efficiency of your heating system. A compromised or inefficient heat exchanger can lead to wasted energy and higher utility bills.

- By maintaining a properly functioning heat exchanger, homeowners can optimize their heating systems for maximum energy efficiency, reducing their environmental footprint and utility costs.

Types of Furnace Heat Exchangers

Heat exchangers come in various types, each with its own set of advantages and considerations. Understanding the different types can help homeowners make informed decisions when selecting or maintaining their heating systems.

Tubular Heat Exchangers

- Tubular heat exchangers consist of a series of tubes through which hot gases pass. These tubes are typically made of materials such as stainless steel or aluminum, which have excellent heat transfer properties.

- Tubular heat exchangers are known for their durability and resistance to corrosion, making them a popular choice for both residential and commercial heating systems.

Plate Heat Exchangers

- Plate heat exchangers utilize a series of metal plates stacked together to create a large surface area for heat transfer. These plates are typically made of materials such as stainless steel or titanium.

- Plate heat exchangers are known for their compact design and efficient heat transfer capabilities. They are commonly used in applications where space is limited or where a high degree of heat exchange is required.

Common Issues with Furnace Heat Exchangers

Despite their importance, heat exchangers are susceptible to various issues that can affect their performance and longevity. This may lead to the need for professional furnace repair. Being aware of these common issues can help homeowners identify and address problems before they escalate.

Cracks and Damage

- Cracks or damage to the heat exchanger can occur due to factors such as thermal stress, corrosion, or improper maintenance. These cracks can allow combustion gases to escape into the air stream, posing a safety hazard to occupants.

- Regular inspections and maintenance are essential for detecting and addressing any cracks or damage to the heat exchanger promptly. In some cases, repairing or replacing the heat exchanger may be necessary to ensure safe and efficient operation.

Corrosion

- Corrosion is a common issue with heat exchangers, particularly in areas with high humidity or where corrosive substances are present in the combustion gases. Corrosion can weaken the metal surfaces of the heat exchanger, leading to leaks or failures.

- Preventative measures such as applying protective coatings or using corrosion-resistant materials can help mitigate the effects of corrosion on heat exchangers. Regular furnace cleaning and maintenance can also help remove corrosive substances and prolong the lifespan of the heat exchanger.

Importance of Regular Maintenance

Regular maintenance is essential for ensuring the optimal performance and longevity of a heat exchanger. By implementing a proactive maintenance routine, homeowners can identify and address issues early, preventing costly repairs and ensuring safe operation.

Cleaning and Inspection

- Regular cleaning and inspection of the heat exchanger are essential for removing any buildup of debris, dust, or other contaminants that can impede airflow and heat transfer. Inspections should be conducted by qualified technicians to identify any signs of damage or wear.

- Cleaning should be performed according to manufacturer guidelines using appropriate tools and techniques to avoid damaging the heat exchanger. In some cases, professional cleaning may be necessary to remove stubborn buildup or deposits.

Air Filter Maintenance

- The air filter plays a crucial role in protecting the heat exchanger by trapping dust, dirt, and other particles that can accumulate on its surface. Clogged or dirty air filters can restrict airflow, leading to overheating and potential damage to the heat exchanger.

- Homeowners should regularly inspect and replace air filters according to manufacturer recommendations to ensure optimal airflow and prevent damage to the heat exchanger. This simple maintenance task can significantly extend the lifespan of the heat exchanger and improve overall system efficiency.

Signs of a Faulty Furnace Heat Exchanger

Detecting issues with a heat exchanger early is crucial for preventing safety hazards and costly repairs. Homeowners should be aware of the common signs indicating a faulty heat exchanger and seek professional assistance if any of these symptoms are present.

Strange Odors

- Strange odors emanating from the furnace or ductwork can be a sign of a cracked heat exchanger. These odors are often described as metallic or burning and may indicate that combustion gases are leaking into the air stream.

- If unusual odors are detected, homeowners should immediately turn off the furnace and contact a qualified HVAC technician to inspect the heat exchanger and address any issues.

Carbon Monoxide Detection

- Carbon monoxide is a colorless, odorless gas produced as a byproduct of combustion. A faulty heat exchanger can cause carbon monoxide to leak into the air stream, posing a serious health risk to occupants.

- Installing carbon monoxide detectors near the furnace and throughout the home is essential for detecting any leaks and alerting occupants to potential hazards. Regular heating system maintenance and inspections of the heat exchanger can help prevent carbon monoxide leaks and ensure safe operation.

Upgrading and Replacement Considerations

As technology advances, homeowners may find themselves considering upgrades or replacements for their heat exchangers. Upgrading to a more modern and efficient heat exchanger can offer several benefits, including improved energy efficiency and enhanced performance. However, before making such decisions, there are crucial considerations to keep in mind.

Energy Efficiency Ratings

- Newer heat exchangers often come with higher energy efficiency ratings, indicating their ability to convert more of the fuel into usable heat. Upgrading to a higher-efficiency model can lead to reduced energy consumption and lower utility bills.

- When considering an upgrade, homeowners should research and compare the energy efficiency ratings of different heat exchangers to make an informed decision that aligns with their energy-saving goals.

Compatibility with Existing System

- Before opting for an upgrade, it’s crucial to assess the compatibility of the new heat exchanger with the existing heating system. In some cases, system modifications or adjustments may be necessary to ensure a seamless integration.

- Consulting with HVAC technicians can provide valuable insights into compatibility issues and help homeowners determine the most suitable options for their specific heating systems.

Professional Inspection and Installation Services

Whether it’s routine maintenance, troubleshooting issues, or considering an upgrade, involving qualified HVAC professionals is essential. Certified technicians possess the expertise and knowledge to ensure the proper functioning and safety of heat exchangers.

Regular Professional Inspections

- Scheduling regular inspections by HVAC professionals is vital for detecting potential issues with the heat exchanger before they escalate. Professionals can perform thorough examinations, checking for cracks, corrosion, and other signs of wear.

- Homeowners should adhere to recommended inspection schedules and promptly address any concerns raised by HVAC technicians to maintain the efficiency and safety of their heating systems.

Installation by Certified Technicians

- When installing a new heat exchanger or replacing an existing one, relying on certified technicians is crucial. Proper installation ensures that the heat exchanger functions optimally and adheres to safety standards.

- DIY installations may lead to errors that compromise the efficiency and safety of the heating system. Hiring professionals guarantees a seamless installation process and provides homeowners with peace of mind regarding the reliability of their heat exchangers.

How To Fix Heat Exchanger

1. Identify the Cracked Heat Exchanger

- Conduct a visual inspection: Begin by visually inspecting your heating system to identify any visible cracks on the heat exchanger. Look for signs of corrosion, rust, or unusual discoloration, as these may indicate a crack.

- Hire a professional technician: If you are unable to visually confirm the crack, it is essential to hire a licensed HVAC professional to perform a thorough inspection using specialized tools and techniques.

2. Determine the Severity of the Crack

- Visual assessment: Assess the size and location of the crack. Small, superficial cracks may be manageable, while larger or deeper cracks may necessitate more extensive furnace repairs or even replacement.

- Conduct a thorough inspection: A professional technician can use advanced diagnostic tools, such as infrared cameras and gas analyzers, to determine the severity of the crack and assess its impact on the overall functionality of the heat exchanger.

3. Evaluate the Age and Condition of the Heat Exchanger

- Consider the age of the heat exchanger: Older heat exchangers may be more prone to cracks and other issues due to wear and tear. If your heat exchanger is approaching the end of its expected lifespan, replacement may be a more cost-effective and long-term solution.

- Assess the overall condition: Evaluate the general condition of the heat exchanger, including signs of corrosion, rust, or other forms of deterioration. This assessment will help determine whether repair or replacement is the most suitable option.

4. Implement Temporary Solutions for Immediate Safety

- Shut down the heating system: If a cracked heat exchanger is identified and poses an immediate safety risk, turn off the heating system to prevent further damage or the release of harmful gases.

- Install a carbon monoxide detector: As a precautionary measure, install a carbon monoxide detector near the heating system. This will provide an early warning in case there is a leak caused by the cracked heat exchanger.

5. Consult with HVAC Professionals for Expert Advice

- Seek multiple opinions: Before making a decision, consult with multiple HVAC professionals to get different perspectives on the severity of the crack and the recommended course of action.

- Request detailed estimates: Obtain detailed estimates from different professionals, including the cost of repairs and potential replacement. This will help you make an informed decision based on both the financial and safety aspects.

6. Consider Repair Options

- Welding or sealing: For smaller cracks, welding or sealing may be viable repair options. However, it is crucial to consult with a skilled technician to ensure that the repair is both effective and safe.

- Epoxy or heat-resistant sealants: Certain types of epoxy or heat-resistant sealants may be suitable for minor cracks. Again, professional guidance is essential to determine the appropriateness of these solutions.

7. Evaluate the Cost-effectiveness of Repair vs. Replacement

- Compare repair costs: Obtain quotes for repairing the cracked heat exchanger and compare them with the cost of a complete replacement. Consider the long-term benefits and potential energy savings associated with a new, more efficient heat exchanger.

- Energy efficiency considerations: Newer heat exchangers are often more energy-efficient, which can lead to cost savings over time. Factor in the potential energy efficiency gains when deciding between repair and replacement.

8. Schedule Regular Maintenance to Prevent Future Issues

- Regular inspections: Implement a routine maintenance schedule with HVAC professionals to detect and address potential issues before they escalate.

- Clean and inspect: Regularly clean and inspect the furnace heat exchanger to prevent the accumulation of dirt, debris, and corrosive materials that could contribute to cracks.

Conclusion

In conclusion, the heat exchanger is a critical component of residential heating systems, responsible for transferring heat from the combustion process to the air circulated throughout the home. By implementing a proactive maintenance routine from the experts at Einstein Heating and Cooling and addressing any issues promptly, homeowners can enjoy reliable and efficient heating performance for years to come.